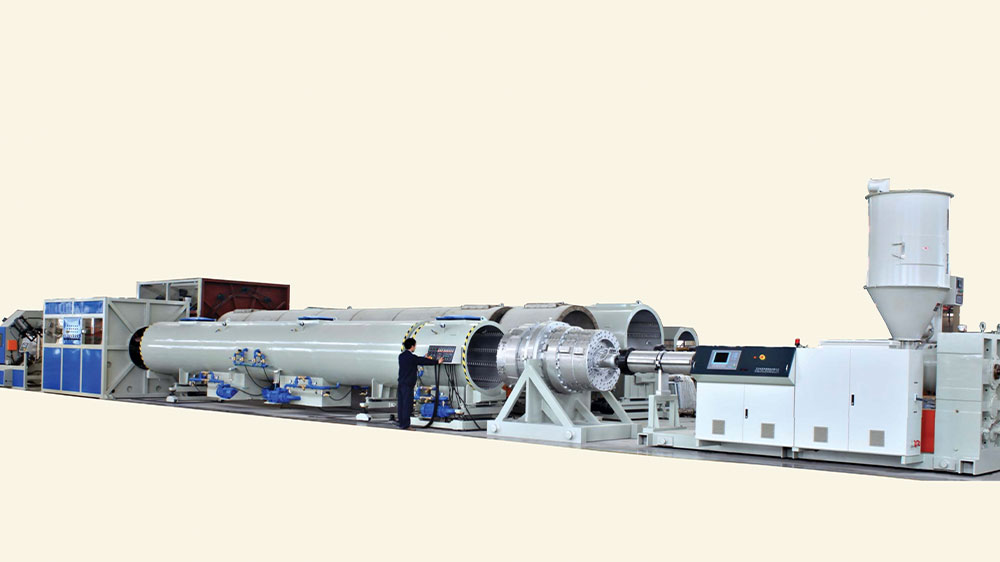

PE PP PC ipayipi ipayipi extrusion umshini

Incazelo Yemikhiqizo

>> Umshini Wokunweba Amapayipi e-PE usetshenziselwa ikakhulukazi ukukhiqiza amapayipi okunisela ezolimo, amapayipi okukhipha amanzi, amapayipi egesi, amapayipi aphakela amanzi, amapayipi epayipi lentambo njll.

>>Ipayipi linezici ezinhle kakhulu ezifana nokumelana nokushisisa, ukumelana nokuguga, amandla amakhulu emishini, ukumelana nokuqhekeka kwemvelo, ukumelana kahle ne-creep, njll. ulayini wethu wokukhipha uklanywe nge-extruder esebenza kahle kakhulu futhi ufakwe isinciphisajubane esinesivinini esikhulu nesiphansi. umsindo, iyunithi ye-Gravimetric dosing kanye nenkomba yokuqina kwe-ultrasonic ingahlanganiswa ngokuvumelana nesidingo samakhasimende sokukhuphuka okunembayo kwamapayipi.

>> Isixazululo sokhiye we-Turn singanikezwa, njenge-laser printer crusher, i-shredder, i-chiller yamanzi, i-compressor yomoya njll. ukuze kuzuzwe ukukhiqizwa kweshubhu okuzenzakalelayo.

>>Ukugeleza Kwenqubo: Impahla eluhlaza+ Amaqoqo Ayinhloko → Ukuxuba → Isiphakeli Sevacuum → I-Plastic Hopper Drier→ Isikulufu Esisodwa Isikhiphi →I-Co-extruder yentambo yombala Nezendlalelo Eziningi → Isikhunta → Ithangi Lokulinganisa Vacuum → Fafaza Ithangi Lamanzi Apholisayo → Ukukhipha → Alukho Uthuli I-Cutter → I-Double/Single disc Winding/Stacker → Ukuhlola Umkhiqizo Wokugcina &Ukupakisha

1. I-Single Screw Extruder

I-extruder yesikulufu esisodwa ingakhiqiza izinhlobo eziningi zemikhiqizo yepulasitiki njengefilimu, ipayipi, ibhodi, i-braid, ibhande nama-granules.

2. Ipayipi le-PE lifa ikhanda

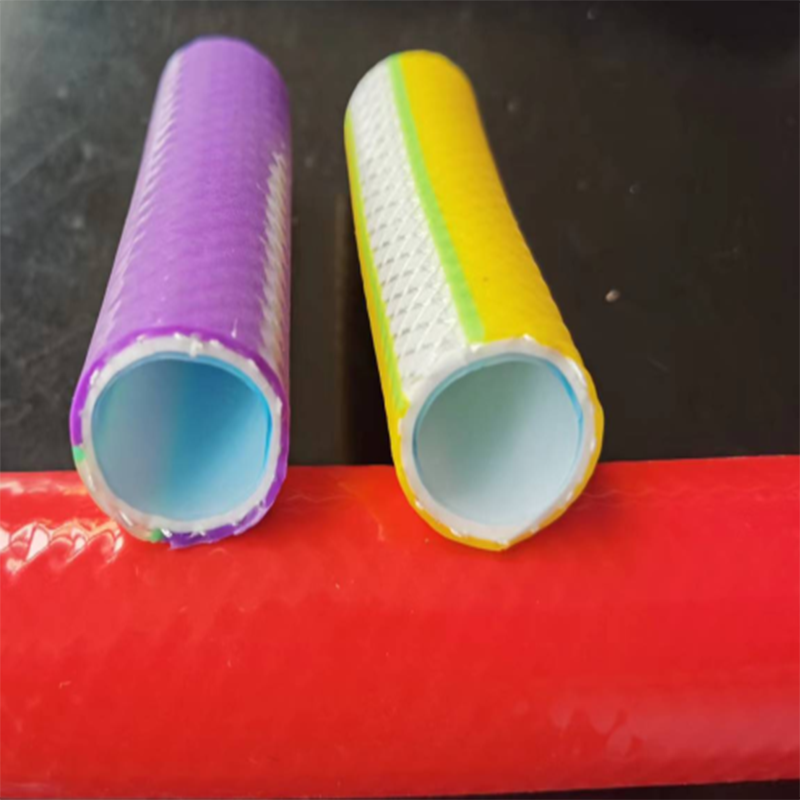

>> Ifanele i-HDPE, i-LDPE, i-PERT, i-PP, i-PPB, i-PPH, i-PP-R, ukukhiqizwa kwamapayipi e-PS

>>Ububanzi bobubanzi busuka ku-Ø16 kuye ku-Ø1600 mm

>> High melt homogenity

>> Umfutho ophansi owakhelwe ngisho nemiphumela ephezulu

>>Ncibilikisa uhlelo lokusabalalisa isiteshi

>> Ifakwe izifudumezi ze-seramic

>> Inqola yekhanda lamapayipi ukuze ihambe kalula

>> Amakhanda epayipi aklanywe ngokwezidingo zohlelo lokusebenza.

>> Ukulungiswa okulula sibonga ukwakhiwa okuklanywe okulungiselelwe nokufakazelwe.

Eminyakeni yamuva, imakethe yamapayipi epulasitiki ikhula kancane kancane eChina.Ipayipi le-PE, PPR kanye ne-UPVC lidlala indima ebalulekile.Lapho ukuthuthukiswa kwepayipi le-PE kuphawuleka kakhulu.Ipayipi le-PE linokusetshenziswa okubanzi.ipayipi lamanzi negesi ingenye yezimakethe ezinkulu zokufaka izicelo.

Sisebenzisa uhlaka oluphelele losekelo lwendlela egelezayo kanye namadivayisi okuthola indawo akhiphekayo

Ukwakhiwa kwesiteshi kugweme indawo efile nokugcinwa.

Umklamo olungiselelwe wesiteshi esigelezayo usinikeza ukumelana nomthelela onamandla.

Kulula ukuhlanganisa nokuqaqa.

I-vacuum calibration tank

>>Ifanele ukukhiqizwa kwepayipi le-PE

>>Ububanzi bobubanzi busuka ku-Ø16 kuye ku-Ø1600 mm

>> Ubude bufika ku-12000mm

>> Insimbi engagqwali engu-304 enendawo yangaphandle ependiwe

>> Izifutho zamanzi ezikhethekile zisendaweni engcono kakhulu yokupholisa ipayipi ngendlela efanele

>> Izisekelo zepayipi ezikhethekile nezilungiswa kalula kububanzi bepayipi ngalinye

>>Ivacuum efakiwe namaphampu amanzi angasebenza ngaphandle kokulungiswa isikhathi eside

>> Amabhavu okupholisa akhethekile angakhelwa ukukhiqizwa kwe-extrusion ethile

Susa umshini

>>Ibanga lamapayipi ukusuka ku-Ø16 kuye ku-Ø1600 mm

>> Amandla okudonsa aphezulu ngaphandle kokulahlekelwa ukuma kwamapayipi

>> Ifakwe 2, 3, 4, 6, 8,10 noma 12 amacimbi ngokusho isicelo

>> Ukushayela kwe-Servo motor ngokuhlinzeka nge-torque ezinzile nokusebenza

>> Ukuma okuhamba ngezimoto kwezibungu ezingezansi

>> Ukusebenza okulula

>> Isivikelo esivalwe ngokuphelele sokuphepha okuphezulu

>>Izihambisi zamaketanga ezinamaphedi enjoloba akhethekile emaketangeni angenalo uphawu epayipini.

>>Ukuvumelanisa nesivinini sesikulufa se-extruder kuvumela ukukhiqizwa okuzinzile phakathi nokushintsha isivinini sokukhiqiza

Isistimu yokusika

>> Ukuvumelanisa okuzenzakalelayo nesivinini se-extrusion

>>Iplanethi ifakwe idiski kanye nesigayo sokusika nokusika

>> I-chip-free ifakwe i-disk blade yokuqinisekisa indawo yokusika epholile ngaphandle kothuli

>> Iphaneli yokulawula isikrini

>Konke ukunyakaza kunemoto futhi kulawulwa iphaneli yokulawula

>> Ukuvinjwa kwamapayipi ngokusebenzisa i-clamping yendawo yonke ukuze usebenze kalula

>> Uhlobo lweyunithi yokusika lukhethwa luncike kupayipi

>>Izidingo zokunakekelwa okuncane

>> Umshini ovalwe ngokuphelele futhi ovikelekile ukuze uphephe kakhulu

Amapharamitha womkhiqizo

| Ibanga lobubanzi(mm) | Imodeli ye-Extruder | Ubukhulu.Amandla(kg/h) | Ubukhulu.isivinini somugqa(m/min) | Amandla e-Extruder (KW) |

| Ф20-63 | SJ65/33 | 220 | 12 | 55 |

| Ф20-63 | SJ60/38 | 460 | 30 | 110 |

| Ф20-63 Okubili | SJ60/38 | 460 | 15×2 | 110 |

| Ф20-110 | SJ65/33 | 220 | 12 | 55 |

| Ф20-110 | SJ60/38 | 460 | 30 | 110 |

| Ф20-160 | SJ60/38 | 460 | 15 | 110 |

| Ф50-250 | SJ75/38 | 600 | 12 | 160 |

| Ф110-450 | SJ90/38 | 850 | 8 | 250 |

| Ф250-630 | SJ90/38 | 1,050 | 4 | 280 |

| Ф500-800 | SJ120/38 | 1,300 | 2 | 315 |

| Ф710-1200 | SJ120/38 | 1,450 | 1 | 355 |

| Ф1000-1600 | SJ90/38 SJ90/38 | 1,900 | 0.6 | 280 280 |