I-Granulator

Ikhwalithi ephezulu ephumayo ephezulu eshisayo ye-plastic pellet/ipayipi/cubeextruder umshini wokwenza izinto kabusha zepulasitiki

I-SJ series single screw extruder plastic machine isebenza ikakhulukazi ekukhipheni i-PP, i-PE, i-PET, i-PVC, i-ABS, i-PS, i-PA ect material. Ithatha ibhokisi legiya elikhethekile, futhi inezici zomsindo ophansi, ukugijima okuzinzile, umthamo wokuthwala ophezulu, impilo ende yesevisi. .Ifakwe isikhunta esihlukile kanye nezinto ezisizayo, ingakhiqiza ipayipi lepulasitiki, ishidi, ibhodi, ama-granules nokunye .Inezici zenqubo elula, okukhiphayo okuphezulu, ukucindezela okuzinzile kwe-extrusion, nezindleko eziphansi.

| Iphrojekthi: I-DJ85 single screw pelletizing line |

| Impahla nefomula | PE amafilimu |

| Umkhiqizo wokugcina | Izinhlamvu ze-PE |

| Umthamo wokukhiphayo | 120-200kg/h , kuncike ezicini zezinto ezibonakalayo. |

| Ubude obumaphakathi | 1.14m |

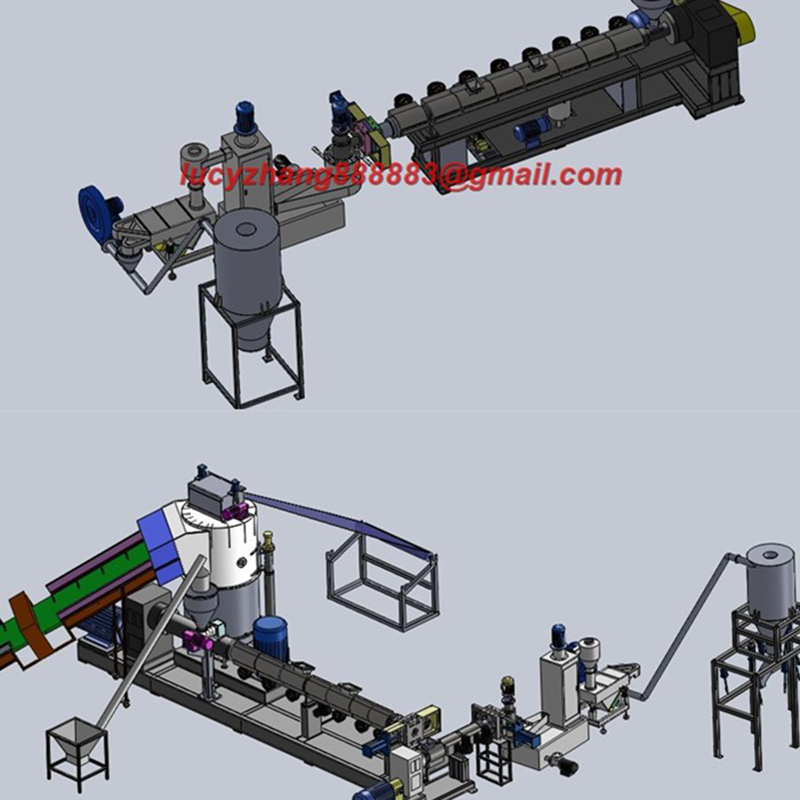

pp pelletizing line plastic recycling umshini granulating imfucumfucu plastic umshini wokwenza umshini

Amapharamitha(CS Series Double Stage Compactor-Granulator):

| Imodeli(isiteji esikabili) | CS85-100 | I-CS100-120 | CS130-150 | I-CS160-180 | CS180-200 |

| Isikulufa Ububanzi(mm) | 85 | 100 | 130 | 160 | 180 |

| L/D | 25-42 | 25-42 | 25-33 | 25-33 | 25-33 |

| Amandla(kg/h) | 150-200 | 300-350 | 500 | 600-700 | 800-1000 |

Isicelo:

Ifilimu ye-PE, i-PP, usilika, ama-Flakes (≤0.5mm), izikhwama, njll.

Qaphela, i-CS yethu yochungechunge lwe-compactor granulator ingaba indlela yokusika imichilo, noma indlela yokusika indandatho yamanzi ngenketho

Kuhlanganisa I:

Isithumeli sebhande(umtshina wensimbi) → Ikhompatha → I-extruder eyinhloko(isistimu yokukhipha umoya ovacuum) → Isishintshi sesikrini esisebenza nge-hydraulic → I-Extruder →

Isiguquli sesikrini se-hydraulic → Isistimu yokusika indandatho yamanzi → Umshini wokukhipha amanzi → Uhlelo lokushaya umoya → Ihopper yesitoreji → iKhabhinethi yokulawula

1. ulwazi oluvamile

1.1Indawo yaphansi

Ukwakhiwa okuyisisekelo, umsebenzi womhlaba, umsebenzi wodonga kufanele uqedwe kahle nguMthengi ngokwamukela lo mugqa we-pelletizing.

Umthengi kufanele ahlinzeke nge-crane, i-forklift noma ezinye izinto zokuphakamisa, izinto zokukhweza namathuluzi.

Indawo: izoklanywa ngokuya ngesakhiwo somugqa.

1.2Ukunikezwa kwamandla kagesi

Amandla afakiwe:106KW (ukusetshenziswa kwamandla okungokoqobo kuzoba ngu-70%)

Ukunikezwa kwamandla kagesi:

I-voltage yokuhlinzeka: 3*380V+N+PE;

Ukubekezelelana kwamandla kagesi: + 10%/-5%;

I-voltage yokulawula: 24VDC + 220VAC;

Imvamisa: 50Hz+-2%

Izintambo/amakhebuli:

- Izintambo/amakhebuli asuka kugesi ukuya ekulawuleni ikhabhinethi (ehlinzekwa nguMthengi).

- Zonke izintambo zikagesi ezisuka kukhabethe lokulawula ziye emshinini ngamunye (zihlinzekwe nguMthengi).

1.3Ukunikezwa kwamanzi

Ukusetshenziswa:0.6T/h (ama-recycles amanzi)

Amanzi okupholisa:

Ngaphandle kwamaminerali ancibilikisiwe noma amisiwe njengephosphor, isulfure, insimbi, njll.

Izinga lokushisa elingenayo T1: ubuningi.15℃

Izinga lokushisa eliphumayo T2: T2=T1+5℃

Ingcindezi yokungena, amaminithi: amabha angu-2.5

Ukuqina: 5-8ºdH;

I-Reflux: ngaphandle kwengcindezi

Ipayipi lamanzi:

Ukusuka kokuphakelwa kwamanzi kuye kuwo wonke umshini owodwa (ohlinzekwe nguMthengi).

1.4Umoya ocindezelwe:0.6M3/min, 0.4~0.7Mpa

1.5Abasebenzi bokusebenza

2-3 Abantu

1.6Amafutha okugcoba

Kutholwe emakethe yendawo ngesincomo soMdayisi (kuhlinzekwa nguMthengi).

2. Imigomo yezohwebo

2. 1Machine uhlu & Intengo

| Cha. | Igama Ledivayisi | Imodeli | Ubuningi(sethiwe) |

| 1 | Isihambisi sebhande | | 1 |

| 2 | Ikhompiyutha | | 1 |

| 3 | I-DJ85/33 i-screw extruder eyodwa | DJ85/33 | 1 |

| 4 | Uhlobo lwepuleti lokushintsha isikrini se-Hydraulic160 | | 1 |

| 5 | Uhlelo lokusika indandatho yamanzi | | 1 |

| 6 | Umshini wokukhipha amanzi esikrinini odlidlizayo | | 1 |

| 7 | Isilo | | 1 |

| 8 | Ikhabethe likagesi | | 1 |

2.2 Imibandela yokukhokha

- 40% njengediphozithi ngo-T/T.

- 60% njengebhalansi nge-T/T ngaphambi kokulethwa nangemuva kokuhlolwa.

2.3 Isikhathi sokulethwa

Ezinsukwini ezingama-50 zokusebenza kusukela ngedethi yokuthola idiphozithi.

2.4 Ukupakisha

Ifilimu yepulasitiki.

2.5 Iwaranti

Izinyanga eziyi-13 zezingxenye zemishini kusukela ngosuku lokukhokha.Isiqinisekiso sezinyanga ezintathu sezinto zikagesi uma ukunikezwa kwamandla embonini yoMthengi kuzinzile.

I-cuishi izokhokhisa Intengo yezindleko Zomthengi zezingxenye ezisele ngemuva kokuthi okokusebenza kuphelelwe iwaranti futhi inikeze umhlahlandlela wobuchwepheshe wesikhathi eside.

2.6 Ukufakwa kanye Nokusebenza

- Umthengi kufanele alungiselele ukufakwa lapho okokusebenza sekufikile, njengokuphakelwa kukagesi, ukuhlinzekwa kwamanzi, izisebenzi namakhreni, njll.

- i-cuishi izolungiselela isicelo se-visa sonjiniyela, abazoya efektri yoMthengi ukuze bathole umsebenzi.

- Umthengi kufanele akhokhele onjiniyela amathikithi endiza okuya nokubuya uma isicelo se-visa sivunyiwe, kanye nezindleko zebhere ezikhiqizwayo njengezinqubo ze-visa, ukudla, indawo yokuhlala kanye nesibonelelo sika-USD100 ngosuku kunjiniyela ngamunye.

2.7 Ukuba semthethweni

- Izinsuku ezingama-60 kusukela osukwini lwekhotheshini.

3. Ukucaciswa kobuchwepheshe

3.1DJ85 I-scruder yesikulufa esisodwa

| 1 | Isihambisi sebhande |

| | Njengomklamo ojwayelekile, imfucumfucu yepulasitiki efana nefilimu, usilika, intambo, izikhwama, izindwangu ezingalukiwe zihanjiswa emgqonyeni wokuhlanganisa wesistimu ye-cuishi ngokusebenzisa idivayisi yokuphakela ibhande.Isivinini sokudlulisa sedivayisi yokuphakela ibhande sixhunyaniswa nokugcwala komgqomo wokuhlanganisa, futhi isivinini sokudlulisa semfucumfucu silungiswa ngokuzenzakalelayo ngokuvumelana nokugcwala kwe-compaction bin.Amandla eMotor: 1.5kw Ububanzi besithumeli sebhande: 400mm Ubude bezinto zokuhamba: 5000mm Ngomtshina wensimbi: uphawu lwesiShayina |

| 2 | Ikhompiyutha |

| | Ummese ogudlukayo osemgqonyeni wokuhlanganisa uyazungeza ukusika nokuchoboza udoti ongena emgqonyeni.Ummese ophenduphendukayo onesivinini esikhulu, ngenkathi uchoboza okokusebenza, ukhiqiza ukushisa okungqubuzanayo ukomisa kusengaphambili imfucuza.Ngesikhathi esifanayo, ngosizo lwesistimu yokulawula izinga lokushisa eklanyelwe ngokukhethekile kanye nesistimu yokulawula isivinini, imfucumfucu ebamba ukushisa icutshungulwa ngaphambili ngaphansi kwezinga lokushisa lokuncibilika.shwabana.Imfucuza yangaphambi kokushwabana ihlanganiswe umsele womhlahlandlela ngaphakathi kodonga lwesisele, bese iphoqelelwa emgqonyeni wokuphakela we-extruder ngamandla amaphakathi ommese ozungezayo.Ngale nqubo edidiyelwe yokuchotshozwa, ukomiswa kanye nokuhlanganisa, ukuzinza kanye nokusebenza kahle okuphezulu kokuphakela imfucuza ngobuningi obuncane obuncane kuyaqinisekiswa. Amandla emoto: 37kw Ukulawula izinga lokushisa Indlela yokupholisa: ukupholisa amanzi Inqwaba yama-rotary blades: 4PCS Inqwaba yama-blade angashintshi:9PCS Ukuzala: NSK Izingxenye ezixhunywe nempahla iyinsimbi engagqwali |

| 3 | I-DJ85/33 I-scruder yesikulufa esisodwa |

| | Isigaba senqubo esikhethekile (umgqomo, isikulufu) esiklanyelwe izinhlobo ezahlukene ze-wastemateria singancibilika futhi senze ipulasitiki izinto ezilahlwayo ezihlanganiswe ngaphambili ngobumnene. Imfucuza yepulasitiki izoncibilika ngokuphelele futhi yenziwe ipulasitiki ngaphakathi kwenqubo yokuklama okuhlosiwe ubude be-32D kuya ku-36D. I-gearbox:i-torque ephezulu, umsindo ophansi, amazinyo aqinile agaya ibhokisi legiya elinomjikelezo wokupholisa wangaphandle Amandla emoto: 55kw, Ukulawula imvamisa nge-inverter Isivinini se-screw: 0 ~ 120rpm Impahla yesikulufu nomgqomo: 38CrMoA1A, ukwelashwa kwe-nitride Ubukhulu bokwelashwa kwangaphakathi: 0.4 ~ 0.7mm, I-L/D: 33:1 Ububanzi be-screw: φ85mm Indlela yokupholisa: phoqa umoya indlela yokupholisa Indlela yokushisa: ngama-heaters Indawo yokushisisa 6 Amandla okushisa angaba ngu-48KW Indlela yokupholisa Ifeni yokupholisa: 0.33KW X 5 = 1.65KW I-Double Vacuum Degassing System: Iphampu ye-vacuum: 2.2kw Isitayela sokuhlunga:ukuhlunga amanzi. Igumbi le-vacuum: idizayini ekhethekile, izindawo eziphindwe kabili. Vacuum tube: izinga lokushisa kanye nengcindezi ukumelana amashubhu. Ukukhipha okusebenzayo okuguquguqukayo njengama-micro-molecule kanye nomswakama osuka ekuncibilikeni ukuze kuthuthukiswe ikhwalithi yama-granules. Isistimu yokuzivikela: Ukuvikelwa komthwalo omningi wemoto. Ukuvikelwa kwengcindezi ngokweqile kwesikulufa. |

| 4 | Uhlobo lwepuleti lokushintsha isikrini se-Hydraulic160 |

| |  | Ubukhulu (mm) | | d1 | d2 | d3 | d4 | h1 | h2 | D1 | D2 | D3 | N-M1 | N-M2 | L | W | H | | Φ280 | Φ254 | Φ254 | Φ280 | 6 | 6 | Φ380 | Φ330 | Φ266 | 12-M24 | 8-M20 | 420 | 230 | 480 | | Indawo yokuhlunga | Amandla | Amandla okushisa | Amandla kagesi | Ingcindezi | Izinga lokushisa | | 550 cm² | ≤2200kg/h | 10.2kw | 3 kw | ≤35MPa | ≤350℃ | |

| Isishintshi sesikrini se-double-plate eyodwa: · Ihitha emise okwendandatho yokufudumeza okungashintshi futhi okuzinzile. · Ukusebenza okungavuzi nokushintsha kwesikrini okusheshayo. · Idivayisi yokubeka uphawu eguquguqukayo. · Isikrini esingagqwali: ukunemba okuphezulu, ukumelana nokugqoka kanye nokumelana nokucindezela. Ububanzi: 160 mm Amandla enjini ye-hydraulic: 2.2kw |

| 5 | Uhlelo lokusika indandatho yamanzi |

| |     |

| | 1. Ijubane le-pelletizing blade lilungiswa ngokuzenzakalelayo kuze kuvele ama-pellets okugcina iyunifomu.2.Idivayisi yomoya isetshenziselwa ukuphakela ummese ukuqinisekisa ukuthintana okuhle phakathi kwe i-blade ne-die, kanye nokucindezela kommese kulungiswa ngokuzenzakalelayo qinisekisa amandla okusika iyunifomu yommese. Qala uhlelo ngokhiye owodwa ukuze wenze ukusebenza kwalo lonke uhlelo kube ngaphezulu elula; Umsiki wobuso obuvundlile Amandla okusika: 2.2kw Amandla epompo yamanzi: 2.2kw I-cutter iwukulawula imvamisa nge-inverter |

| 6 | Umshini wokukhipha amanzi esikrinini odlidlizayo |

| Isikrini sokudlidliza esithuthukisiwe sokukhipha amanzi esithuthukisiwe esihlanganiswe nokomiswa kwe-centrifugal okuvundlile singafinyelela ukusebenza okuhle kakhulu kokumisa kanye nokusetshenziswa kwamandla okuphansi.I-cuishi ithatha idizayini evaliwe futhi ifakwe isembozo esingazwakali, esinomsindo ophansi futhi esisebenziseka kalula. Amandla emoto: 0.25kw*2. Izingxenye ezithinta amanzi: SUS304. Hlanganisa izisefo: hhayi ezishiselwe.Kufakwe futhi kulungiswe ngezikulufo, ukuze kube lula ukufaka izisefo ezintsha ngokuzayo. Iziphethu zizungezwe ngenjoloba, ukuvimbela umehluko omkhulu we-amplitude obangelwa ukuguga kwentwasahlobo. Idizayini ekhethekile yokuvimbela ukungcola okuncane ukuwela empompini yamanzi. Amandla emoto: 3kw. Isivinini sokujikeleza: 1460rpm Izingxenye ezithinta amanzi nama-granules: SUS304. |

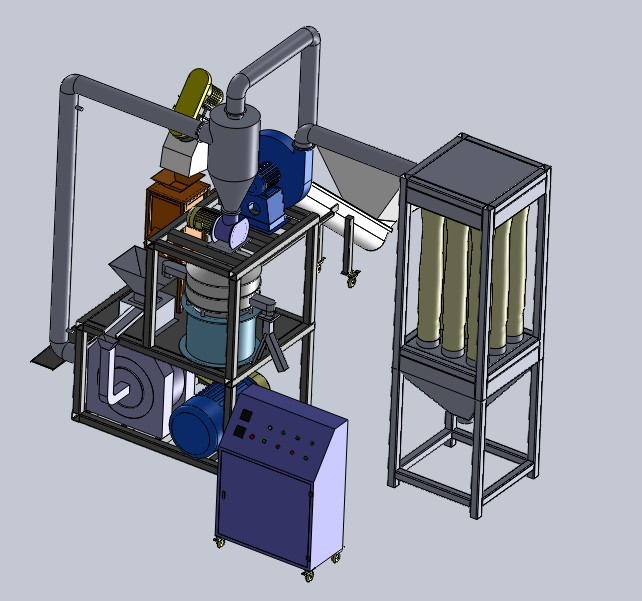

| 7 | Isilo |

| | Umthamo osebenzayo: 700LMaterial yengxenye ekuthintaneni nensimbi engagqwali |

| 8 | Ikhabethe likagesi |

| | Uhlelo lokulawula lwamukela isilawuli se-Siemens, futhi ifakwe isikrini sokuthinta sezinga lezimboni (into yokuzikhethela) - I-Smart on: Ibhuthi yokhiye owodwa

Ngokokulandelana okunengqondo okusethiwe kanye nezidingo zenqubo yokusingatha izinto, isistimu ye-cuishi exhunyiwe ibona ukuqalisa kokhiye owodwa, ngaleyo ndlela igwema amaphutha enqubweni yokuqala yokwenziwa ngesandla. - Ukuvala shaqa okuhlakaniphile: ukuvala ukhiye owodwa

Ngosizo lweyunithi eyenziwe ngokwezifiso, isistimu ye-cuishi ingakwazi ukubona ukuvala ukhiye owodwa wemodyuli yesistimu yonke ukugwema ukulimala kwemishini okubangelwa ukusebenza okungalungile ngesikhathi sokuvala ngesandla. - Idivayisi yokumisa izimo eziphuthumayo

i-cuishi ifakwe umsebenzi wokumisa izimo eziphuthumayo, osetshenziswa njengesimo esiphuthumayo sezingozi ezingaqinisekile ngesikhathi sokusebenza komshini, ukuvala lonke uhlelo ngokushesha futhi ngokushesha ukugwema izingozi zesibili nokulimala. Idivayisi yokuvikela ukuphepha kwempilo Uhlelo lwe-cuishi lucabangela ngokugcwele izindaba zokuphepha zemishini ngesikhathi sokusebenza.Isiteshi ngasinye esisebenzayo kanye nendawo ejikelezayo yengxenye kufakwe amaswishi okuphepha e-elekthronikhi ukuze kuqinisekiswe ukuphepha kwezinto zokusebenza ngesikhathi sokusebenza futhi kugwenywe izingozi ezingaba khona ngesikhathi sokusebenza kwesisetshenziswa esidala ukulimala kubaqhubi bekhasimende. - Ukugcinwa kokusebenza kwepulasitiki

Ngosizo lwesistimu yokulawula ukushisa okunembile kanye nomklamo ohlosiwe wokuthuthukisa wesigaba senqubo ye-plasticizing, uhlelo lwe-cuishi lungaqinisekisa ukwethembeka nokuzinza kwekhwalithi yokugcina ye-pelleting. - Idivayisi yokuvikela ukushisa ngokweqile kwegumbi lokuhlanganisa

Ngosizo lwesimiso sokulawula se-modular kanye nokuqaphela okugcwele kokusebenza kwezinto ezihlukene ezigaywe kabusha, isistimu ye-cuishi ingaqinisekisa ukuthi udoti ocutshungulwayo ufinyelela isimo esifanelekile sokushisa kanye nokuhlanganisa ekamelweni lokuhlanganisa, futhi lingagwema izinto ezibuyiswayo zepulasitiki ekuhlanganisweni. .Ukushisa ngokweqile noma ukuwohloka endaweni yokugcina impahla. Oxhumana naye: Schneider Ukudluliselwa: CHNT Ukushintsha okujwayelekile: CHNT I-Circuit-breaker: CHNT Qaphela: Ikhasimende lidinga ukuhlinzeka ngocingo olusuka kukhabethe lokulawula ukuya emshinini ngamunye.

|